As an oil-free, high-efficiency and environmentally friendly vacuum solution, dry vacuum system has been continuously expanding its application in many industries in recent years, and its technological upgrading and industry suitability are constantly improving. The following is a comprehensive analysis of the solutions in this field from three dimensions: industry applications, technical advantages and future trends:

1. **Pharmaceutical industry**

- **Aseptic production and GMP certification**: High-temperature-resistant dry pumps meet GMP requirements for suspended particle concentration (ISO5 level) and microbial contamination control (≤1CFU/m³) in the clean zone through oil-free design (to avoid oil mist contamination), high-temperature resistance (stable operation at 350°C), and intelligent control system (pressure/temperature/vibration monitoring). For example, after a biopharmaceutical company adopted the dry pump, the maintenance cycle was extended to 6,000 hours, the equipment availability rate was increased to 99.6%, and the freeze-drying cycle was shortened by 23%.

- **Sterilization and Cleaning Validation**: Modular design reduces chamber disassembly time to 15 minutes, supports superheated water sterilization (121°C for 30 minutes), and meets GMP sterilization standards.

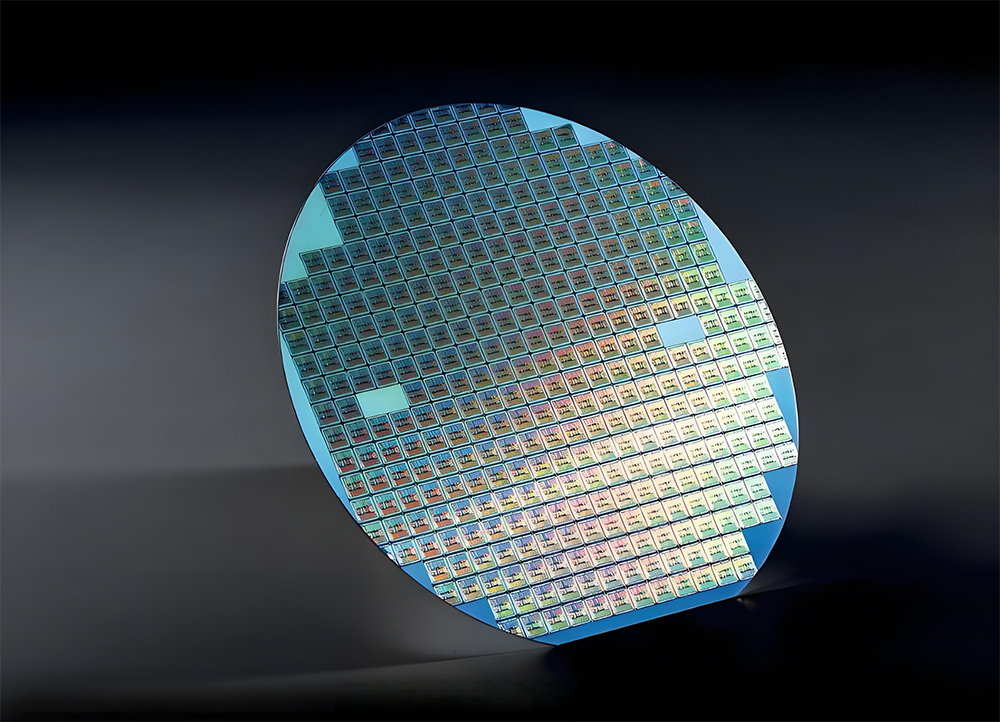

2. **Semiconductor manufacturing**

- **High-purity vacuum environment**: Semiconductor-grade dry vacuum pumps (e.g., Beijing Tongjia products) provide ultra-high vacuum environment (ultimate vacuum up to 0.05 mbar) in thin-film deposition, etching, ion implantation, and other processes to meet the demand for 3nm/2nm advanced processes. The localization rate is less than 5%, but domestic substitution is accelerating, and the domestic market share is expected to increase to 25% in 2025.

- **Energy saving and intelligence**: integrated frequency conversion control technology, energy consumption is reduced by 18% compared with traditional equipment, while real-time data monitoring is realized through the Internet of Things, and troubleshooting time is shortened by 75%.

3. **New energy (lithium battery/photovoltaic)**

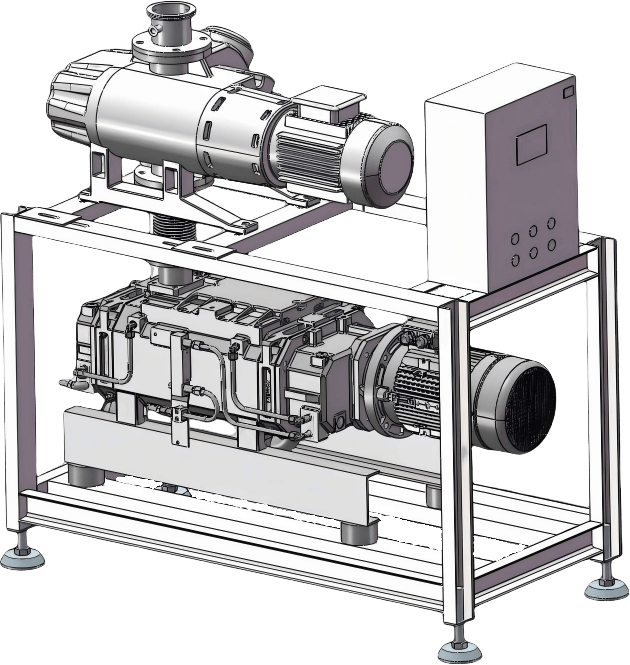

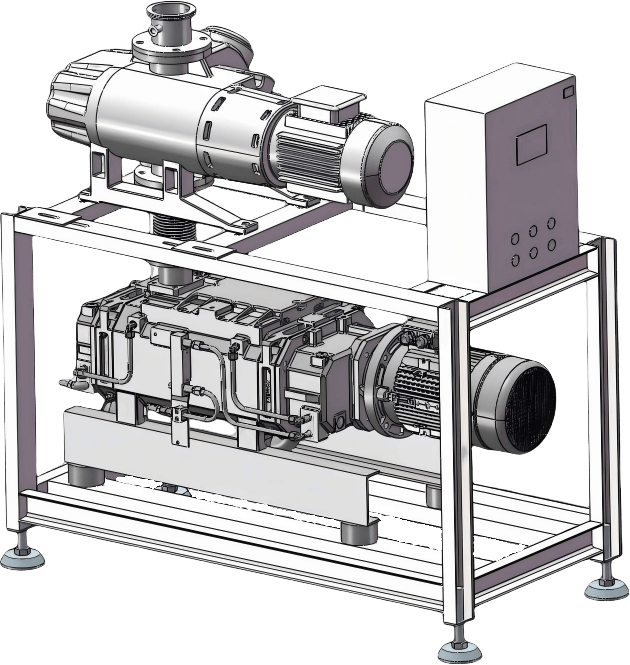

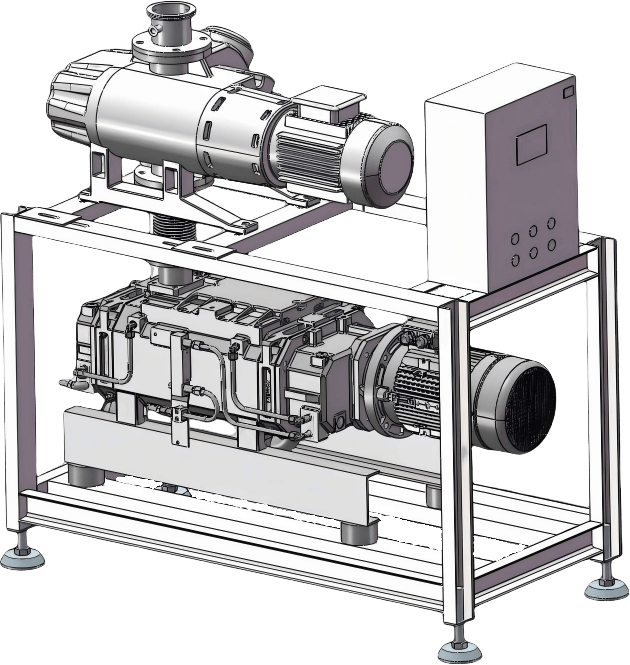

- **Power Battery Manufacturing**: Edwards GXS dry screw vacuum pump realizes ultimate vacuum <1Pa in liquid injection and drying, steam handling capacity is improved, combined with frequency conversion motor drive, energy consumption is reduced and no waste oil emission. The maintenance cycle is up to 5 years, which significantly reduces the production cost.

- **Photovoltaic and semiconductor process **: modular system adapted to fiber optic production, wafer manufacturing and other scenarios, pumping rate fluctuations are controlled within ± 1.5%, to ensure production continuity.

4. **Chemical & Environmental**

- **Solvent Recovery and Emission Reduction**: Roots liquid ring vacuum system can recover 98% solvents, together with MVR evaporation system (energy consumption reduced by more than 60%), applied to wastewater concentration, waste acid recovery and other processes. The solution of Bozhong Industry realizes the green transformation through the full closed-loop temperature control system.

- **Corrosion resistance and high reliability**: 316L stainless steel pump body and perfluoroether rubber seals are used to adapt to the environment of chemically active gases and prolong the life of the equipment.

1. **Oil-free design and environmental friendliness**

Dry vacuum pumps avoid lubricant contamination through non-contact construction (e.g., claw, screw) and ensure high-purity vacuum environments, especially for the semiconductor and pharmaceutical industries. The Edwards GXS series utilizes dry screw technology with zero exhaust emissions, supporting green manufacturing.

2. **Energy efficient and intelligent**

- Variable frequency drive technology reduces energy consumption (e.g., 22% reduction in energy consumption for the GXS series), and intelligent systems enable early warning of failures (predicting bearing wear 72 hours in advance).

- Modular design improves maintenance efficiency, e.g. the Roots pump system of Bozhong Industry supports rapid integration and reduces installation costs.

3. **Material & Process Breakthroughs**

- Multi-layer composite ceramic coated rotor (hardness HRA92) and spiral groove sealing structure to enhance stability in high temperature environments.

- Semiconductor grade pump body materials (e.g., high temperature resistant alloys) are ASME BPE certified to meet the demands of demanding processes.

1. **Domestic substitution and technological breakthrough**

The global market has long been dominated by international giants such as Edwards and Ebara (CR5 over 70%), but domestic companies (e.g., Beijing Tongjia and Bozhong Industry) have accelerated their substitution through technological iteration and are expected to grab 15%-20% of the market share in the field of dry pumps.

2. **Intelligent and Green Manufacturing**

- AI predictive maintenance and IoT technologies will reduce operating costs, such as the digital factory project that has increased spare parts turnover by 40%.

- Oil-free design combined with long life (>10 years maintenance cycle) is becoming mainstream in response to global emission reduction policies.

3. **Emerging Areas of Expansion**

Quantum computing, photonic chips and other cutting-edge technologies require more stringent vacuum environment (such as EUV lithography supporting pumps), promoting the research and development of ultra-high vacuum technology (≤ 10-¹¹ Pa).

Through technological innovation and industry adaptation, the dry vacuum system industry has formed mature solutions in the fields of pharmaceuticals, semiconductors, new energy, etc., and will focus on domestic substitution, intellectualization and green transformation in the future. Enterprises need to choose modular design (such as high-temperature, explosion-proof) to optimize the production efficiency of the specific scenarios, while paying attention to policy guidance (such as the “14th Five-Year Plan”) and technology iteration trends.

SINCE

1987

Follow Public